Synbone

This page documents early Synbone development and the design philosophy behind anatomically and mechanically realistic training models used in orthopaedic education. It focuses on practical and technical aspects relevant to the author’s involvement.

Author context: Oscar Baldomero — early Synbone development, anatomical model building, and surgical training materials.

Contents

1 — Origins and context

Orthopaedic surgical training courses in Davos pre-dated the foundation of Synbone. In the early period, plastic bone models were supplied by an external manufacturer (Contraves). These models enabled basic procedural training, but their quality was regarded as insufficient for more advanced educational requirements. In addition, the AO sought greater control over the full design and manufacturing process in order to align training materials more closely with evolving surgical techniques and teaching objectives.

Synbone emerged in this context: as a practical response to defined training needs, with an emphasis on reproducible manufacture, anatomical plausibility, and—critically—mechanical similarity to the biological structures being simulated.

2 — Foundation and roles

From the beginning, the work required a balance of anatomical understanding and engineering execution. Oscar Baldomero and Mr Steiner were brought on board as the individuals with the know-how to develop and manufacture training models that met both educational and technical requirements. The AO group, as the third partner and majority shareholder, contributed deep knowledge of course design and the practical realities of how models would be used by surgeons at different levels of training.

Mr Steiner’s engineering role extended beyond mould-making. He designed production carousels capable of running multiple moulds simultaneously and undertook development work to ensure that the mechanical behaviour of the manufactured bones matched the required biomechanical characteristics of real bone as closely as possible for training purposes.

3 — Development philosophy

Model development was guided by two parallel aims: visual resemblance and mechanical similarity to the natural structures being simulated. While both were pursued, mechanical similarity was the key criterion because it directly determined how the model behaved under operative handling, drilling, fixation, cutting, and stress.

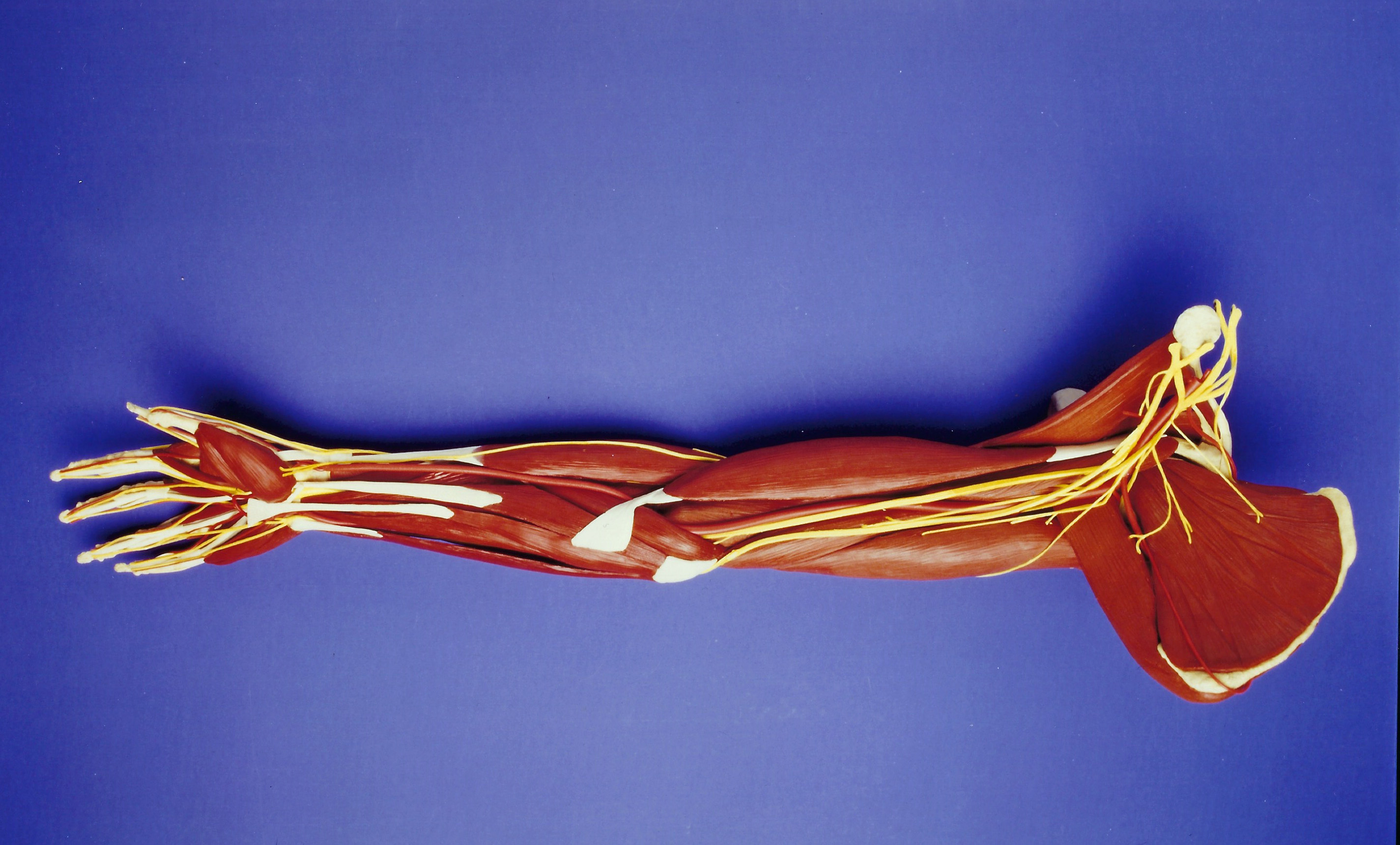

In the early phase, development focused almost exclusively on bony structures—cortical and cancellous components—and on achieving reliable behaviour across a range of models, including long bones and complex geometries such as spinal elements. Soft tissues in this context referred primarily to anatomical structures surrounding bone, especially muscle, ligaments, and tendons (and where relevant, vessels and nerves), developed to support realistic operative exposure and procedural learning.

These models were used in orthopaedic training workshops in Davos and worldwide. Courses were delivered at multiple levels (beginner, intermediate, and advanced), and the material needed to support progressively more complex techniques without compromising consistency or realism.

4 — Representative training models

The following images show a representative soft-tissue training model (“Baldomero Arm”) developed for orthopaedic education. The purpose is not display, but realistic surgical handling: layered access, identification of structures, and repeatable operative manipulation.

5 — Sources

The foundation of Synbone AG and the composition of its initial leadership are documented in primary materials (including foundation documentation and related register extracts). Relevant items can be listed on the Publications page as the source list is assembled.

Note: This page forms part of the historical documentation on balmed.ch.